Technologies, global changes in the economy, the section on the environmental requirement of sustainability, and the multi-dimensional supply chain are transforming the industry of designing, manufacturing, and delivering electronic products radically. With the growth in customer demands and the digitalization trend that has inclined people to adopt and incorporate digital technologies, manufacturers should adapt to the times to remain afloat.

The article discusses the major electronics manufacturing trends, provides some forecasts about the electronics manufacturing over the next decade, and considers the innovations that will characterize the future of the industry.

Key Trends Shaping Electronics Manufacturing

The electronics manufacturing industry is undergoing a dynamic transformation driven by a series of overlapping trends, such as the rise of AI supply chain platform. These are transformations that are redefining the way business is being conducted, created, and argued around the world.

1. Smart Manufacturing and Industry 4.0

Combined with the application of cyber-physical systems, the Internet of Things (IoT), and advanced analytics, the application of smart factories is transforming traditional factories into data-driven and smart factories. Industry 4.0 allows measuring it in real-time, predictive keeping up, and running sharp automation to guarantee performance and reduce stoppages.

2. Micro-Electronics and Miniaturization High-Density electronics

Consumer electronics are going smaller, and the associated miniaturization methods are being adopted by manufacturers. This presents the issue of the accuracy of strong assembly, artful PCB planning, and materials that have the ability to host small, bulletproof parts.

3. Circular Economy and Sustainability

The push to go green is influenced by environmental issues and regulatory pressure in order to encourage manufacturers and other producers to be more sustainable. It can be seen in energy-efficient manufacturing lines, recyclable materials, and waste reduction measures, but also in the middle of strategic planning.

4. Digitization and Resilience of Supply Chain

To create more resilient, adaptive networks, manufacturers are starting to invest in the digitization of the supply chain, such as by using AI and blockchain from platforms such as Luminovo, to provide both transparency and forecasting.

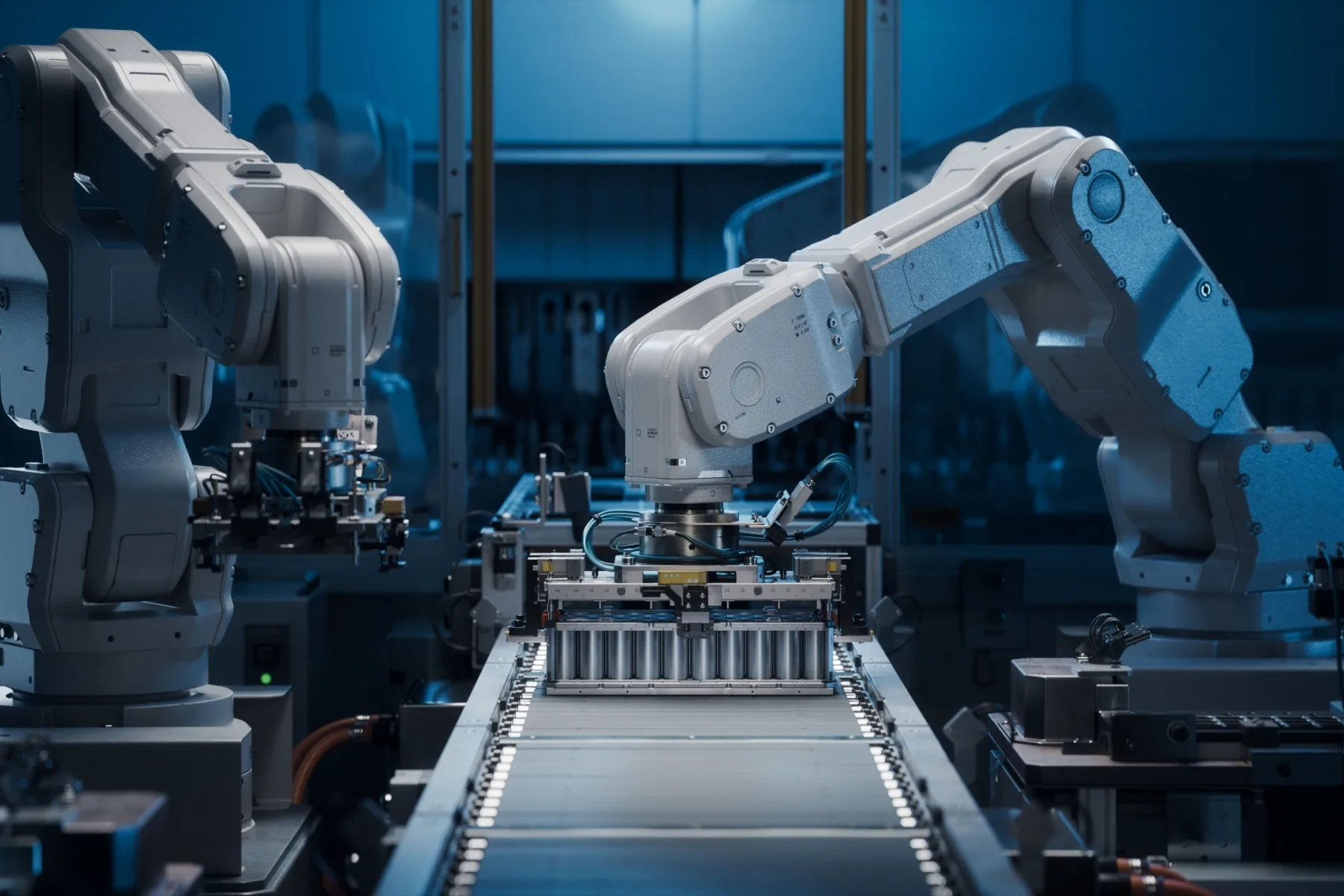

5. Increased Robotics and Automation

Brands are more likely to invest in the increased use of robotics and automation technologies. Automation in the form of the robotic arm on an assembly line to autonomous material handling devices is redefining the workforce.

Predictions for the Next Decade

In terms of the future, electronics manufacturing trends will be incomparably changed by 2035. 92% of companies have started taking steps to solve supply chain issues. These are some of the major estimations drawn by current patterns.

1. Mass Adoption of AI in Manufacturing Operations

Artificial Intelligence (AI) is going to be the key in making decisions, including optimization of production schedules, identification of defects on the fly, etc. Predictive analytics will cut corners, decrease expenses, and increase the quality of the produced products.

2. On-Demand and Localized Manufacturing

The consequences of the global instability and transportation choke points will be the decentralization of manufacturing. An increasing number of companies will switch to local/regional manufacturing and use on-demand manufacturing technologies.

3. Human-Machine Collaboration

Instead of the displacement of human labor entirely, the sophistication of automation will shift towards cooperation. The cobot or collaborative robots will be used in parallel with human operators, doing the same job repeatedly, increasing productivity and safety.

4. Increased Attentiveness to Computer Security

Cybersecurity will also be an important electronics manufacturing innovation as factories and manufacturers will have to protect intellectual property, avoid production shutdowns caused by hacking attacks, and address strict regulations on the protection of data.

5. Competitive Green Manufacturing

The term sustainability will transition to a competitive advantage. The organizations that dominate the carbon-neutral production, sustainable packaging, and energy optimization will be strategically by being environmentally friendly to their investors and consumers.

Challenges to Overcome

Though the future electronics industry predictions are very promising, a manufacturer has to face serious challenges to remain competitive:

Shortage of Skilled Labor

- Challenges associated with the recruitment of workers in automation, AI, and robotics

- Reskilling and upskilling of the current employees

- Knowledge gap due to the lack of technicians

Multi-Faceted Supply Chain Management

- Reliance on spatial suppliers

- Heightened vulnerability to political, economic as well as environmental shocks

- Diversification, sourcing, and logistical pressure

Adherence to Global regulations

- Navigating safety and sustainability standards used in different regions

- Material compliance tracking ( e.g., RoHS, REACH)

- Following the changing export/import laws

Integration of Legacy System

- Inability to interface old systems with new-age digital channels

- Danger of data silo constrained visibility and efficiency

- Organizational Culture Resistance to the change of technology

Innovations Driving the Future of Manufacturing

Electronics industry predictions include various new technologies that are pushing forward the development and creating new grounds for expansion:

Digital Twins

- Digital simulations of the products, equipments, or the whole factories

- Before a physical implementation, simulation and testing of performance are done

- Live optimization and troubleshooting

- Increased speed of design, less waste of material

Advanced Materials

- Stretchable, conformable, and wearable electronics

- Nano materials with superior conductivity and scale-down properties

- Sustainable bio-based materials

AI and Edge Computing Integration

- Real-time local decision processing

- Fewer cloud add-ons and latency

- More intelligent machines that have AI installed to adapt to use

In Conclusion

Digitalization, sustainability, and automation are the key paradigms that define the future of electronics manufacturing. Smart factories, on-demand supply networks, and sustainable business plans are a welcome addition for industry leaders to sustain increased need. The next 10 years will be characterized by the combination of AI, edge computing, and smart materials, namely their combination, which is to make manufacturing more adaptable, smart, and innovative.